Description

It is versatile and is best suited to apply lubricants to hot mold plungers, shear blade dies, punches, rolls and tools. The Renite E Model Atomizer, operated by compressed air, expands the air to maximum velocity and thoroughly atomizes and sprays lubricant in the exact amount and place required. The instant the air is off, the flow of lubricant automatically stops. The instant the air is on (whether by manual, timer or trip valve), lubricant is atomized and sprayed in a definite quantity, determined by the micrometer adjustment of the knurled cap.

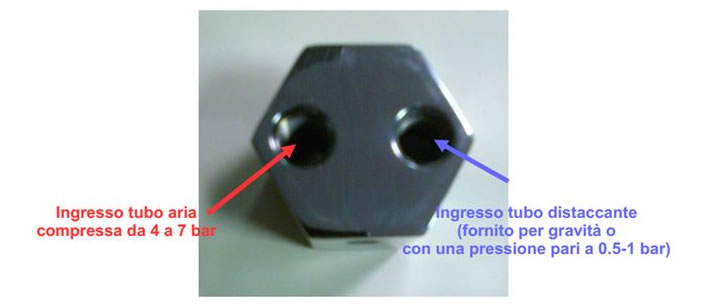

Renite E Atomizer has two inlets (see photo above), one for the lubricant (detacher) and the other for air only.

This means that the lubricant can be supplied either by gravity even with no head or by less than 5 p.s.i. pressure using the TANK&PUMP SYSTEM MODEL # 40 in order to saturate the atomizer without lubricant comeing out from the nozzle. Thus the lubricant must reach the atomizer directly from the container, arranged, for example, 7 feet tall, or directly from the TANK&PUMP SYSTEM MODEL # 40.

Finally the atomization will occur only when it will open the source of compressed air from 25 to 100 p.s.i.

Renite E atomizer can spray up to 600 – 700 mm and it can have a straight pattern, narrow cone or an helical pattern, wider.

When the “E” Model is approximately 2″ away from the mold surface, the Helical Tip pattern is approximately 2.5″ in diameter and the Straight Tip pattern is approximately 1.75″ in diameter.

This compact, sturdy Atomizer is precision-made entirely from brass, bronze and steel. It has no leather, packing, rubber, composition or solder.